Keeping machinery clean is often seen as a cosmetic detail, but in reality, it determines business performance and profitability. Here we take an in-depth look at the hidden expenses, inefficiencies and long-term consequences that come with neglecting machinery cleaning, and why proactive equipment care is essential across all sectors.

The Overlooked Expense: Why Clean Machinery Matters

For many businesses, clean equipment is wrongly viewed as an aesthetic choice rather than a functional necessity. Yet machinery cleaning directly impacts how well equipment operates. Dirt, dust and grime build up over time, causing moving parts to struggle, seals to fail and cooling systems to clog. This not only leads to breakdowns but also undermines the efficiency and safety of operations.

Industries most at risk include manufacturing, agriculture, logistics and construction. These sectors rely heavily on machinery operating under tough conditions, often exposed to dust, mud, chemicals or debris. Without regular cleaning and machinery maintenance, equipment in these environments deteriorates faster, causing spiralling costs and reduced productivity.

Operational Inefficiencies Caused by Dirty Equipment

Reduced Performance and Downtime

A build-up of grime creates extra friction between moving parts and raises operating temperatures, increasing the likelihood of equipment failure. Over time, this results in more frequent stoppages and unexpected downtime.

Higher Energy Consumption

When machines are dirty, they must work harder to perform the same tasks. This added strain raises energy consumption, meaning businesses face inflated power bills and reduced overall efficiency.

Delays and Workflow Disruption

Both planned maintenance shutdowns and unexpected breakdowns disrupt production schedules. This makes it harder to meet delivery targets and maintain smooth, reliable operations across the business.

Hidden Financial Costs That Escalate

Increased Repair and Maintenance Bills

Dirt accelerates wear on key components such as bearings, belts and seals. This results in more frequent repairs as well as higher replacement and maintenance costs over time.

Shortened Machinery Lifespan

Debris and contamination contribute to premature equipment ageing. Instead of lasting their intended lifespan, machines reach obsolescence faster, forcing businesses to invest in replacements earlier than planned for.

Insurance and Compliance Risks

Failing to meet industry hygiene or safety standards can void warranties or lead to higher insurance premiums. Worse still, non-compliance may result in regulatory fines or legal actions that directly affect the bottom line.

Health, Safety and Legal Consequences

Workplace Hazards

Slippery residues, oil leaks and airborne particles increase the risk of slips, falls and respiratory issues. Dirty machinery becomes a workplace hazard, putting both employees and visitors at risk.

Employee Productivity and Morale

Neglecting equipment hygiene often signals broader operational neglect. Staff working with poorly maintained machinery may feel undervalued, which can affect motivation, productivity and employee retention.

Breaches of Regulation

In the UK, organisations like the Health and Safety Executive (HSE) can impose severe penalties on businesses failing to meet safety standards. Poor machinery cleaning and maintenance practices put companies at risk of enforcement action.

Environmental and Brand Implications

Increased Emissions and Waste

Inefficient machinery releases more emissions, consumes excess fuel and wastes raw materials. This damages a company’s environmental footprint and is detrimental to sustainability efforts.

Damage to Business Reputation

Customers, partners and auditors often view cleanliness as a reflection of professionalism. Dirty equipment can harm a company’s image; reducing trust and impacting future opportunities.

Solutions and Best Practices

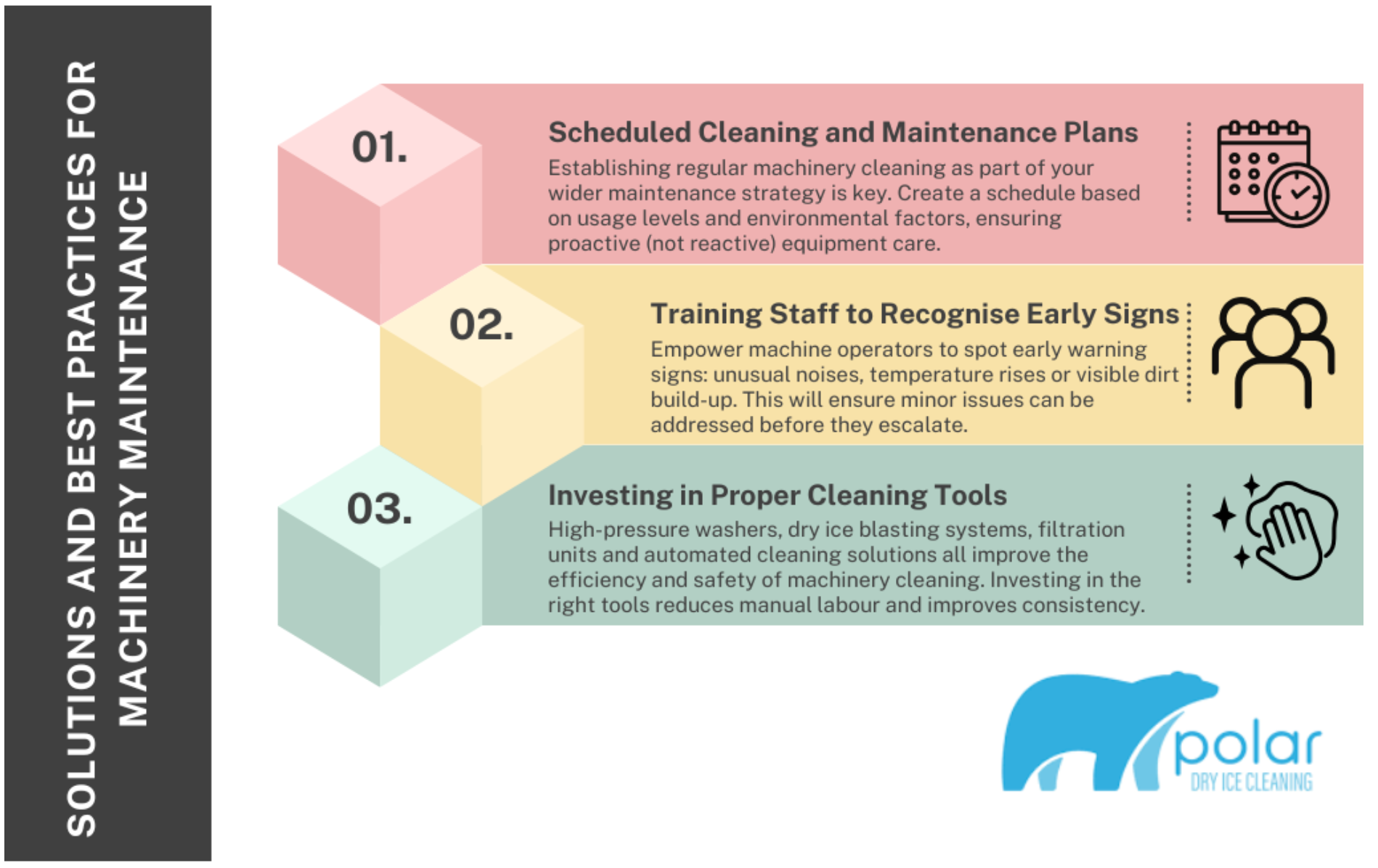

Scheduled Cleaning and Maintenance Plans

Establishing regular machinery cleaning as part of your wider maintenance strategy is key. Create a schedule based on usage levels and environmental factors, ensuring proactive (not reactive) equipment care.

Training Staff to Recognise Early Signs

Empower machine operators to spot early warning signs: unusual noises, temperature rises or visible dirt build-up. This will ensure minor issues can be addressed before they escalate.

Investing in Proper Cleaning Tools

High-pressure washers, dry ice blasting systems, filtration units and automated cleaning solutions all improve the efficiency and safety of machinery cleaning. Investing in the right tools reduces manual labour and improves consistency.

Clean Machines, Lean Business

Maintaining clean machinery is an essential part of running a lean, cost-effective and resilient business. From reducing repair bills and energy use to improving safety and extending equipment lifespan, regular cleaning offers measurable long-term benefits. By prioritising machinery cleaning, companies can cut unnecessary costs, minimise risks and achieve stronger operational performance.

Get in touch with Polar Ice Cleaning today to learn how our specialised machinery cleaning services can help protect your equipment and support your business success.