Step into a world where food processing meets innovation, where cleanliness is paramount, and where traditional cleaning methods are a thing of the past.

The Secret Ingredient – Dry Ice Blasting Explained

This ingenious cleaning technique harnesses the power of compressed air to propel minuscule dry ice pellets at supersonic speeds. And here’s the best part – these dry ice pellets undergo sublimation upon impact, transitioning from solid to gas, creating a tiny, powerful explosion that lifts away grime, grease, oils, and contaminants without any abrasive action.

Spotless Sanitation in Seconds:

In the food processing industry, cleanliness is non-negotiable. Dry ice blasting is the superhero that swoops in to save the day, ensuring your equipment is spotless in mere seconds. This means reduced downtime, increased productivity, and a smoother production process. What’s even better is you can keep your production line running while we are blasting away!

Extended Equipment Lifespan:

Your factory equipment deserves some tender loving care, and dry ice blasting provides just that. With its gentle yet powerful cleaning action, this method reduces wear and tear, extending the lifespan of your valuable machinery. Enjoy cost savings that will make your financial team applaud!

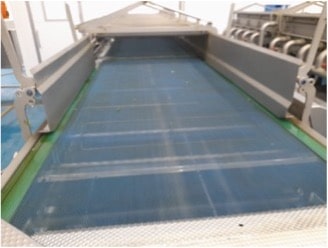

Versatility:

From commercial ovens to conveyor belts, dry ice blasting can tackle it all. It’s a versatile solution perfect for different food processing equipment, making it a must-have practice in your kitchen’s cleaning arsenal.

Preserving Purity and Taste:

Taste is everything in the culinary world, and dry ice blasting preserves it flawlessly. By eliminating unwanted residue from machinery and surfaces, this innovative cleaning method maintains the purity and integrity of your food products.

Sustainable and Environmentally Friendly:

Sustainability is the trend that never goes out of style, and dry ice blasting is leading the charge. Embrace a greener approach to food processing with this eco-conscious solution that utilises recycled CO2. It leaves behind no harmful by-products, making it the perfect recipe for an environmentally friendly factory.

Safety First, Always:

In the food industry, safety is paramount. Dry ice blasting checks all the boxes by eliminating the need for harsh chemicals and solvents.